Monitoring of fuel consumption and GHG emissions from international shipping is currently under discussion at the EU level as well as at the IMO. There are several approaches to monitoring, each with different characteristics. Important differences exist with regards to the costs of the equipment, operational costs, the accuracy of the measurements, and the potential to monitor emissions of gases other than CO2. Moreover, some approaches offer more opportunities to improve the operational fuel-efficiency of ships and fit better to possible future policies than others.

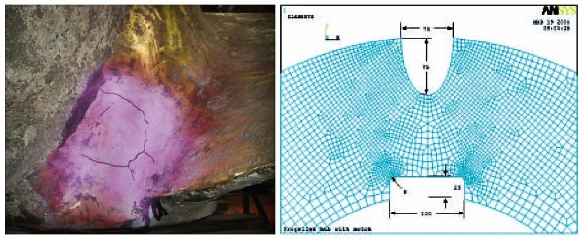

Incident Information on Cracks in Propeller Hub

This incident refers to cracks identified in a vessel’s propeller hub. When carrying out hull renewal survey in drydock, two open cracks were found during the visual inspection of the propeller hub. The propeller was a 4 bladed mono-block fixed pitch manganese aluminium bronze propeller fitted with cone and key and with diameter: 5205 mm.

Incident Information on Thermal Oil Heater Fire in the Funnel

This incident is referring to a vessel which had an exhaust gas heated Thermal Oil installation. The thermal oil circulating pump stopped and the stand-by pump did not start. No alarm indicating abnormal condition was given. The thermal oil system temperature and pressure increased until the safety valve directed the oil into the compensating (expansion) tank. The expansion tank overflowed (again no alarm was given) through its air vent head. The air vent head was mounted inside the funnel, close to the exhaust pipes. An explosion was heard from the funnel followed by a fire.

Engine Worn Out by Catalytic Fines

DNV has over the last years seen an increase in engine damage due to catalytic fines, even though the bunkered fuel has been in accordance with ISO 8217 marine fuel specification and fuel treatment is standard procedure and implemented for all vessels. Damage (incident occurred in 2010), that can be traced back to catalytic fines occurred after only 100 running hours, making the engine totally inoperable. All pistons and liners were totally destroyed and had to be changed.

Typical Cracks in Deck of Oil Tankers

Cracks in deck plating in way of deck penetrations of oil tankers has been an increasing problem and is typical on vessels with high strength steel in deck and most typically found on Buoy loading Oil Tankers trading in the North Sea. The damaged areas (as shown in this post) were limited to cracks in the upper deck plating in way of the pipe penetrations resulting in small leaks, but could easily have resulted in more serious damage to the deck structure and the safety of the ship if left unattended over time.

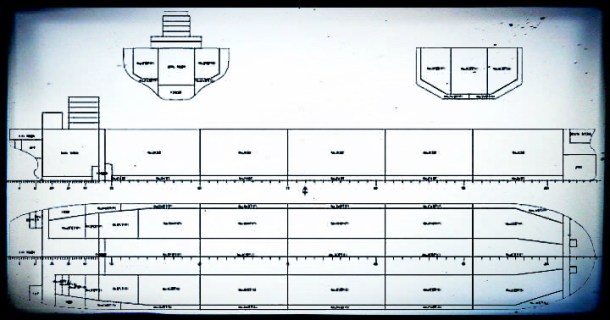

Minimal Ballast Water VLCC Design

On 25 February 2013 Namura Shipbuilding acquired AIP (Approval in Principle) from NKK regarding the MIBS (Minimal Ballast water Ship) VLCC project, for which the company has been working for years together with Shipbuilding Research Centre of Japan and with the support of Japanese Government. This tanker design reduces the weight of ballast water required by about 65 percent compared with a conventional hull form.

Buckling of Bulkheads During Steaming of Tank

A vessel was being prepared for Methanol loading by steaming out the cargo tanks for chloride removal. After steaming out the cargo tank, the duty officer went inside the tank for inspection and found deformed bulkheads.

LNG Fuel Bunkering in Australia

The global sulphur cap of 0.5%, which the International Maritime Organization (IMO) will implement between 2020 and 2025 is expected to accelerate the adoption of LNG as fuel for shipping globally, provided that bunkering infrastructure is available. Corresponding developments for LNG bunkering and phasing-in of LNG fuelled ships have already started, although not in Australia.

MARPOL Annex VI Requirements for Technical and Operational Measures

During last February a very interesting article from Edmund Hughes, Technical Officer, Marine Environment Division, IMO was published in IMO’s website, explaining the new regulations aimed at improving the energy efficiency of international shipping, which entered into force on 1 January 2013 and make mandatory the Energy Efficiency Design Index (EEDI), for new ships, and the Ship Energy Efficiency Management Plan (SEEMP) for all ships. Other amendments to MARPOL Annex VI add new definitions and the requirements for survey and certification, including the format for the International Energy Efficiency Certificate. The regulations apply to all ships of 400 gross tonnage and above. However, under regulation 19, the Administration may waive the requirements for new ships up to a maximum of 4 years.