A 190-meter bulker suffered severe collision damage in Lagos, Nigeria. A large hole in the hull plating prevented the ship from sailing at full speed. The classification society also demanded that the vessel go to drydock immediately unless an on-site solution was found. Hydrex therefore sent a diver/technician team to the vessel’s location to carry out an emergency doubler plate repair at anchorage.

Measuring Ships’ Energy Efficiency

During December 2012 Transport & Environment NGO released a paper investigating opportunities to establish an energy efficiency benchmark measurement. The paper also makes references to different metrics and proposals already under consideration at the IMO or in the EU and identifies possible options in the current EU discussions on monitoring, reporting and verification.

HHI New LNG Storage Tank

Hyundai Heavy Industries (HHI), announced at the end of November that it has developed an independent liquefied natural gas storage tank model, the Lobe-Bundle Tank. The Lobe-Bundle Tank uses ring-shaped plates instead of conventional flat plates to reduce the weight of the tank and building cost significantly. The tank is built using spray-type insulation rather than panel-type insulation, substantially reducing construction time.

Auxiliary Engine Start Up With High Pressure Air From Breathing Apparatus

A standby vessel stationed close to a drilling platform, experienced a “black-out” which was caused by water contamination of fuel and occurred shortly after switching from one service tank to another. The water was drained from the tank and fuel system. The main engine was restarted and was running normally. To provide electric current for lighting, steering etc., one of the auxiliary engines had to be started. Upon trying this, it was discovered that the spare starting air bottle was empty although the pressure gauge indicated full pressure.

New LNG-Fueled Containership Design

LNG-fuelled vessels promise a solution to many of the environmental challenges facing shipping over the next 30 years. To meet the needs to cut CO² emissions and maximize efficiency wherever possible, IPP Ingenieur Partner Pool developed STREAM, the new containership design for LNG-powered containerships. The concept, which has been assessed by GL and given a certificate of approval, is for a range of liner or feeder vessels from 3,000 TEU to 4,200 TEU for worldwide service.

Damage to Exhaust Gas Boiler Due to Dry Running

During morning attendance of engine room, a water leak from the exhaust gas boiler was discovered. In order to get to port, the water circulation was shut off, and the instruction manual on “emergency dry running” was followed. When arriving at anchorage, the exhaust gas boiler overheated, and the crew found that a soot fire had occurred.

Main Engine Damage Due to Fuel Contamination from Dry Cargo

When a bulk carrier was at sea, high exhaust gas temperatures were noted and several piston rings were found broken after investigation. The rings were renewed and engine restarted. After some hours of running the main engine it malfunctioned once again and more broken rings weer found. The broken rings were again replaced, but then the engine failed to start and the vessel had to be towed to port. A considerable number of piston rings were broken. Excessive wear of liners and piston crown grooves were also found. The fuel oil used was suspected to be a probable cause, although the quality of it was not found abnormal according to the test report.

Study on LNG Bunkering in Ports

More stringent air emission requirements for seagoing vessels are introducing a new challenge for maritime administrations and services. These challenges are all the more daunting in the IMO ECAs. One of the possible solutions to compliance is the use of LNG as propulsion fuel for shipping, next to the use of low sulfur fuels and the installation of exhaust gas scrubbers. According to data from engine manufacturer Rolls-Royce, relative emissions for these various compliance options clearly demonstrate LNG propulsion as the overall environmental winner.

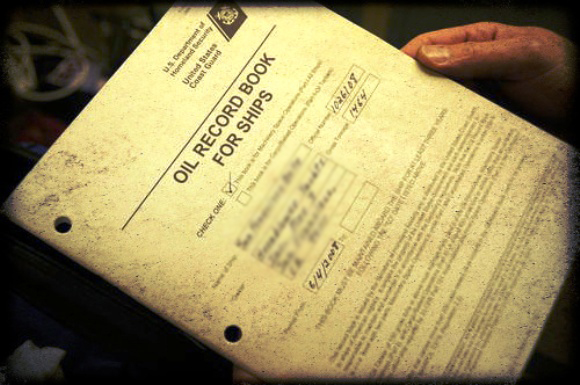

USCG And OWS Violations

The large, green generators in the engine room of a 292-foot ship moored to a pier in San Francisco grind to life, filling the enclosed space with machine-produced roar. Coast Guard inspectors take a few slow laps around the room looking for malfunctions, leaks, fire risks and safety hazards.

Specialized Vessel for the Carriage of Nickel Ore

The world’s first specialized vessel for the carriage of Nickel Ore has been built and registered to the NK class. The vessel, the Jules Garnier II, was built by Naikai Zosen Corporation and delivered to Japanese shipping major JX Shipping Co. Ltd on 19 September 2012, and is the first vessel in the world to be recognized as a Specially Constructed Cargo Ship for the carriage of Nickel Ore in accordance with the IMO’s IMSBC Code. The 27,200 dwt Jules Garnier II is the first vessel in the world to apply ClassNK’s new requirements in its construction and makes use longitudinal bulkheads in in its cargo holds to ensure stability and structural strength even when liquefied nickel ore cargoes are loaded.