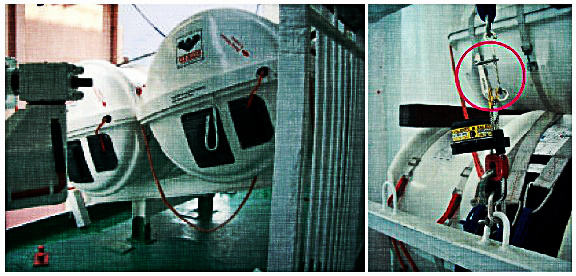

This incident refers to the loss of an inflatable liferaft. The master of a vessel reported that the fastening for one of the liferafts failed whilst the vessel was in port, allowing the liferaft to roll over the side of the ship. The liferaft container landed between the ship and the wharf causing the liferaft to inflate. The inflatable liferaft was retrieved but the container was lost. Luckily no persons were hit by the raft.

Incident Information in Loss of Inflatable Liferaft – Failure of Fastening

Information on Ingress of Water in Immersion Suits due to Deteriorated Glue

This incident information refers to ingress of water in immersion suits as a result of deteriorated glue. During survey for renewal of the Safety Equipment Certificate it was observed leakage on some of the immersion suits. The zipper had become detached from the suit in various places. The same was found at the connection of gloves to the suit. The immersion suits were estimated to be less than 10 years old.

Incident Information on Thermal Oil Heater Fire in the Funnel

This incident is referring to a vessel which had an exhaust gas heated Thermal Oil installation. The thermal oil circulating pump stopped and the stand-by pump did not start. No alarm indicating abnormal condition was given. The thermal oil system temperature and pressure increased until the safety valve directed the oil into the compensating (expansion) tank. The expansion tank overflowed (again no alarm was given) through its air vent head. The air vent head was mounted inside the funnel, close to the exhaust pipes. An explosion was heard from the funnel followed by a fire.

Engine Worn Out by Catalytic Fines

DNV has over the last years seen an increase in engine damage due to catalytic fines, even though the bunkered fuel has been in accordance with ISO 8217 marine fuel specification and fuel treatment is standard procedure and implemented for all vessels. Damage (incident occurred in 2010), that can be traced back to catalytic fines occurred after only 100 running hours, making the engine totally inoperable. All pistons and liners were totally destroyed and had to be changed.

Avoidance of Engine Room Fires

The direct cost of an engine room fire can be in the range of 1–4 million USD for a cargo vessel and much more for a passenger vessel. Off-hire and loss of goodwill adds to this figure and is perhaps the most difficult asset to replace. Engine room fires also represent a hazard for crew members working in that area and fire fighters.

Typical Cracks in Deck of Oil Tankers

Cracks in deck plating in way of deck penetrations of oil tankers has been an increasing problem and is typical on vessels with high strength steel in deck and most typically found on Buoy loading Oil Tankers trading in the North Sea. The damaged areas (as shown in this post) were limited to cracks in the upper deck plating in way of the pipe penetrations resulting in small leaks, but could easily have resulted in more serious damage to the deck structure and the safety of the ship if left unattended over time.

LNG Fuel Bunkering in Australia

The global sulphur cap of 0.5%, which the International Maritime Organization (IMO) will implement between 2020 and 2025 is expected to accelerate the adoption of LNG as fuel for shipping globally, provided that bunkering infrastructure is available. Corresponding developments for LNG bunkering and phasing-in of LNG fuelled ships have already started, although not in Australia.

Engine Room Fire on Mobile Offshore Unit

A fire occurred in the port engine room of a semi-submersible drilling unit whilst carrying out exploration drilling in Norwegian waters. The fire was indicated by alarms in the control room and confirmed by attending personnel. The engine room was successfully isolated manually after approximately 35 minutes, and the halon system was then activated. This, however, did not completely extinguish the fire, which re-ignited. The fire was eventually extinguished some 7 hours after the initial alarm.

Accident With Pilot Ladder

When a vessel was at anchorage, a diving boat was tied up aft of the vessel for some work. A pilot ladder was rigged to let people climb down to the diving boat. While a person was climbing down, the ladder gave way and suffered total rope failure at 6 different points within the top 4 to 5 meters. The person fell and landed on the work deck of the diving boat approximately 10 metres down from the ship’s poop deck.

Air Compressor Accident Kills Crewman

During an operational test on board after a repair/overhaul activity, parts of the air-compressor broke loose. In additions to damage to the compressor, one of the parts from the compressor hit the attending engineer with fatal consequences.