The MINOAS project (Marine Inspection Robotic Assistant System) is an European project under development. The project’s aim is the re-engineering of the methods that are being followed during a vessel inspection. The project introduces the concept of having locomotive robots inspecting a vessel (e.g. a cargo hold) which are under the direct command of a human inspector. Using virtual reality the inspector is able to concept that integrates human personnel with high locomotion-enabled robots, effectively “tele-porting” the human inspector from the vessel’s hold to a control room with virtual reality properties.

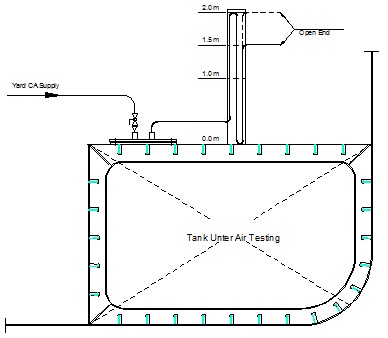

Tanks Air Tightness Testing

Air Tightness Test, is a test to verify the tightness of the structure by means of air pressure difference.

ECA Retrofit Study

New International Maritime Organization (IMO) regulations require that all vessels sailing in the Emission Control Areas (ECA) must reduce sulphur level in fuel oil to 0.1% or clean the exhaust gas to an equivalent level by 2015.

The Danish industry initiative, Green Ship of the Future, has concluded a study on comparing technologies that meet the International Maritime Organization’s emission levels for ships sailing in the Emission Controlled Areas (ECA).

The objective of the study was to compare the potential solutions able to meet the requirements of the IMO regulations regarding SOX in the ECA in 2015 and globally in 2020. Similarly in 2020, the global requirements will be a reduction of sulphur content in the fuel to 0.5% or alternatively the equivalent level measured in the exhaust gas.

Seafarer’s Health & Lifestyle

Physical and mental health problems amongst seafarers are not uncommon particularly if we consider the type and the difficulties of the work that a seafarer has to face onboard.

When thinking of seafarers’ health and lifestyle one should always have in mind just few of the following factors: unstable work schedules and long working hours due to operational needs, the small community which one should adapt and work with, the feeling of being away from home and familiar faces, the difficult working environment as well as all the hazards that are involved, the restricted medical facilities and limited medical supplies, the confined nature of life on board ship, the climate of the area where the ship is operating.

All the above along with the come and go from home nature of the seafaring profession adds pressure to a person, even if he is not realizing it and is not helping in any way to maintain healthy behaviors like frequent exercise, normal sleep intervals, healthy living environment etc.

Oily Water Separators

The story so far

Oily Water Separators (OWS) are being used onboard ships as a regulatory requirement of MARPOL conventions. Their main use is to clear the water that has been accumulated in ship’s bilges and produce water that its contents is within acceptable limits in order to be discharged overboard.

OWS are mainly installed and used onboard to protect the environment and consequently the public interest. Therefore since they don’t produce any “measurable” profit for the ship owner and because they don’t play a critical role to the ship’s structural or operational safety, they don’t get the attention they should be given as a system.

Cargo Residues in Hold Bilge Systems

Before loading the cargo hold of a bulk carrier or a general cargo, appropriate inspections should be conducted in order to ensure that all the systems related to the cargo hold are in good working order. One of the key common issues is the cleaning of the hold from cargo residues. Various debris have the “ability” to find their way into the systems of hold bilges making manual removal of such debris imperative. Debris (especially foodstuff) which have been left in the bilges will decay over time giving some of the most unpleasant smells. Hold bilges are usually cleaned using a shovel and afterwards they must be lifted out of the hold. Once the bilge area has been cleaned the next thing to do is to verify and ensure that the rest of the hold bilge systems are in good working order. Therefore the following should be checked and tested if possible: bilge sounding pipes, bilge suctions, bilge non return valves.

Ship’s Geometry and Hull Definition

The form of a ship’s hull can determine the majority of its attributes; stability characteristics; resistance etc. As a result the power needed for a certain speed can also be determined along with the ship’s seaworthiness; maneuvering capabilities and load carrying capacity.

Aluminum Alloys MIG Welding Procedure Instructions

1. Base-metal preparation:

To weld aluminum alloys, operators must take care to clean the base material and remove any aluminum oxide and hydrocarbon contamination from oils or cutting solvents or NC machines coolants. Aluminum oxide on the surface of the material melts at about 2035o C while the base-material aluminum underneath will melt at 650o C. Therefore, leaving any oxide on the surface of the base material will inhibit penetration of the filler metal into the work piece. To remove aluminum oxides, use a stainless-steel bristle wire brush (and/or grinding) or solvents and etching solutions. If grinding is used for cleaning/preparing weld areas it should be paid attention to the brand used since some grinding wheels use an organic binder that leaves a residue behind, that will possibly cause weld porosity. Thus, it is recommended to test the particular brand of grinding wheels before actual use, in a welding test work piece