If someone wonders why to install a Ballast Water Treatment System, the answer is that it has to do with legislation; one comes from IMO and the other one from USCG. These two are the driving force for all of the suppliers to develop a system and for the shipowners to install a system at some point from today until 2016 and onwards. But before choosing a system, the available technologies have to be checked. I dare to say that nowadays the technologies are pretty mature and there are quite a few of them, so many choices exist for different shipowners, types of vessels and trading routes.

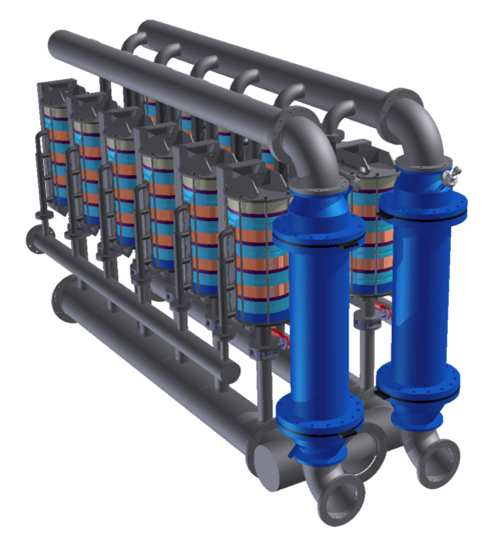

The rule of thumb is the combination of two different treatment stages; the separation stage and the disinfection. Separation is needed to remove large organisms and a large quantity of sediments, to promote the biological efficacy of the total system and one minor thing, really important for the operator though, to reduce wear and tear of the disinfection stage. This is achieved through hydrocyclones or fine filters. The separation stage is followed by the disinfection stage which is implemented to kill organisms and pathogens or to inactivate organisms, as according to the convention the organisms must remain non-viable. The means used for the stage of disinfections are chlorination, UV treatment, ozonation, oxidation, deoxygenation and flocculation. These are the most popular technologies used in the market and surely there are a large number of them.

As for the technologies of Ballast Water Treatment, the total number of systems in the market is 70, from which the 28 are type approved system according to IMO, unofficially there are 35 in total. Different technologies are most suitable for different flow rates. ERMA FIRST was established back in 2009 when a ballast water treatment was fully developed, in scope of the development, design, certification and production of ERMA FIRST Ballast Water Treatment System (BWTS). ERMA FIRST technology is based on hydrocyclons, electrolysis and different models.

As a shipowner or operator you need to know some items when you knock the door of a BWTS supplier. First of all, the size and type of vessel, as one system cannot serve it all. Another important factor is trading routes and ports and the ballast voyage duration. Different treatment technologies require different holding time. The ballast pump type is also important, as well as the ballast pump location, the stripping system details and the approvals of the system. Any specific limitations like water turbidity, salinity and temperature are necessary to be known. You do not want to install a system on an ice class vessel which would have a minimum water salinity of 15°C. Then, there are the pressure requirements to operate efficiently, the pressure drop, the power requirements which are important, especially for the retrofitting market. An important topic which is not addressed openly is the system cleaning requirements. All these information are crucial which will affect your choice.

The installation, especially for a retrofit, is not an easy task. According to my calculations, you need almost a year time from day zero, which is the day that shipowner decides to install a system, until the day that the system is under operation. This process can be divided into different sections.

Installation Steps of a BWTS

As for operating the a BWTS, according to our data more than a 1000 systems have been installed until today, there are less than ten in operation though, meaning that not much experience has been gained. Running these systems before the convention comes into force, is beneficial for the crew, for the supplier and the industry in general. What is required is trained crew, crucial parameters, sampling to analyse specific parameters, documentation for a possible PSC inspection, VGP which is complicating the operation of the systems. The crew should also be fully aware of the maintenance of the system, consumables replacement, trouble shooting and problems reporting which is the only way we us vendors can optimize the system. As this is a new market with limited experience, the experience gained from operating the system day after day is the only feedback in order to make our BWTS system much better.

Above article is an edited version of Mr Konstantinos Stampedakis, General Director of Erma First, presentation during 2013 GREEN4SEA Athens Forum.

You may view relevant video here.

The article was initially published in SAFETY4SEA.

Leave a Comment